Hinokuni Santoku Shirogami #1 210mm (8.3) – SharpEdge

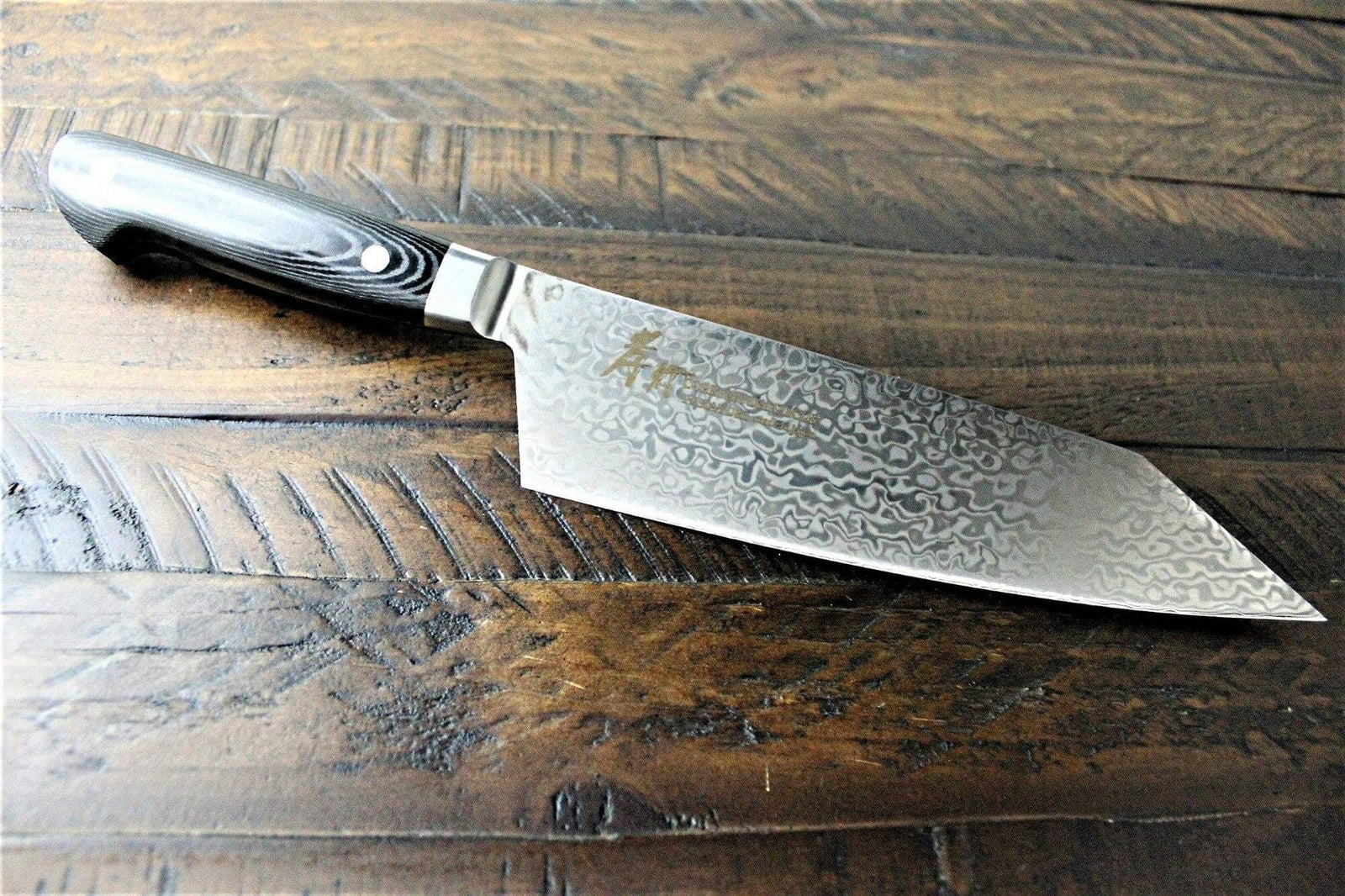

The Hinokuni Santoku is a versatile kitchen knife made entirely by hand by blacksmith Yukihiro-san at his smithy in Kumamoto in the south of Japan. The Hinokuni collection is hand-forged from Shirogami #1 steel laminated in soft iron, so sharpening will be nothing but pure pleasure.Few blacksmiths make their own knives completely in every step of the process from raw material to finished product, and Yukihiro-san is one of them. Working with raw materials is challenging and difficult, but the blacksmith insists on it because he believes that this step is crucial for the quality of the final product. The result of such a long and hard process are sturdy and heavy knives that are real workhorses.❗️ Because they are forged by hand and in small quantities, they take a while to arrive, so here's some good advice: if one of the knives from the Hinokuni series is on your wish list, get it while it's still available.🌋 Hinokuni means "the land of fire", a nickname for Kumamoto Prefecture, home to the famous volcano Mt. Aso.BLADE SHAPE:The longer (210mm / 8.3") and wider (52mm / 2") santoku is a versatile kitchen knife that excels at all kinds of chopping and cutting on the kitchen cutting board. The wide blade allows easy transfer of ingredients from the board to the pot, and the extra weight can be used to cut through tougher ingredients (🚨 but not through bones!). Thanks to its long and thin cutting edge, this knife has no problem with longer cuts and finer techniques such as chopping garlic, dicing or julienne. The cutting edge is fairly straight (giving santoku a limited rocking motion), while the spine of the blade curves towards the tip continuously at an approximately 60-degree angle, making it resemble a sheep's foot.The Japanese word Santoku roughly translates to “knife of three virtues” and may refer to the wide variety of ingredients that the knife can handle: meat, fish and vegetables, or to the tasks it can perform: slicing, chopping and dicing - the emphasis being on the number 3 (San). STEEL:Yukihiro San uses only Shirogami #1 for his kitchen knives, which is very reactive and delicate, but unparalleled in its sharpness.Shirogami #1 is one of the purest steels, and consequently one of the easiest to sharpen. Its characteristics make Shirogami popular with traditional Japanese blacksmiths and sushi masters. The advantage of Shirogami #1 is that it has a very fine, delicate sharpness, is easy to grind and stays sharp for a very long time. It will require a little more attention in maintenance. The blade will acquire a protective patina with use.KNIFE CARE:The steel will gradually acquire a patina, which only endows this knife with more charm. Do not wash this knife in a dishwasher, but rather wash it by hand and wipe it with a dry cloth. The advantage of having a blade made of high carbon steel is the fine sharpness, ease of sharpening, and long edge retention. We recommend the occasional coat of knife maintenance oil to protect the blade from external influences. → Read more about patina on our blog.LAMINATION:The blade was laminated with soft iron, which is iron with only a small amount of carbon added to it. Laminating the blade improves its structural integrity, as the knife’s core is made of hard—and therefore brittle—high-carbon Aogami #2 steel that is prone to breakage on its own.⚠️ Due to its purity and lack of any added elements such as chromium (Cr), soft iron doesn’t resist corrosion well. Therefore, the upper laminated part can also develop rust when not taken care of properly.→ Yukihiro-san laminates the knives himself in his smithy because he sees this as a crucial step in the processing of the blade. The process of laminating different metals is very complex, and most smithies use pre-laminated materials.GEOMETRY:It has a double bevel (symmetrical) blade.BLADE FINISH:The blade sports a beautiful black Kuro-uchi finish. The look of the knife reflects the blacksmith's philosophy and has a touch of rusticity and robustness that comes with the purely handmade blade. The knife has been created with a great deal of pride and skill.HANDLE:The Japanese Wa handle is oval and made in cherry wood with a plastic ferrule. It fits perfectly in the left and right hand.BLACKSMITH:Yukihiro Sakai is a young blacksmith from Kumamoto (Kumamoto Prefecture on the island of Kyushu). He trained with Nishida-san [Nishida Hamono]. Yukihiro-San's recent work is focused on Shirogami #1 with a kuro-uchi finish and evenly ground and flat profiles. His knives are affordable but of superior quality. We anticipate that over the years, the prices of his products will rise due to the superb craftsmanship and his growing popularity.

The Hinokuni Santoku is a versatile kitchen knife made entirely by hand by blacksmith Yukihiro-san at his smithy in Kumamoto in the south of Japan. The Hinokuni collection is hand-forged from Shirogami #1 steel laminated in soft iron, so sharpening will be nothing but pure pleasure.

Few blacksmiths make their own knives completely in every step of the process from raw material to finished product, and Yukihiro-san is one of them. Working with raw materials is challenging and difficult, but the blacksmith insists on it because he believes that this step is crucial for the quality of the final product. The result of such a long and hard process are sturdy and heavy knives that are real workhorses.

❗️ Because they are forged by hand and in small quantities, they take a while to arrive, so here's some good advice: if one of the knives from the Hinokuni series is on your wish list, get it while it's still available.

|

🌋 Hinokuni means the land of fire, a nickname for Kumamoto Prefecture, home to the famous volcano Mt. Aso. |

BLADE SHAPE:

The longer (210mm / 8.3) and wider (52mm / 2) santoku is a versatile kitchen knife that excels at all kinds of chopping and cutting on the kitchen cutting board.

The wide blade allows easy transfer of ingredients from the board to the pot, and the extra weight can be used to cut through tougher ingredients (🚨 but not through bones!). Thanks to its long and thin cutting edge, this knife has no problem with longer cuts and finer techniques such as chopping garlic, dicing or julienne.

The cutting edge is fairly straight (giving santoku a limited rocking motion), while the spine of the blade curves towards the tip continuously at an approximately 60-degree angle, making it resemble a sheep's foot.

The Japanese word Santoku roughly translates to “knife of three virtues” and may refer to the wide variety of ingredients that the knife can handle: meat, fish and vegetables, or to the tasks it can perform: slicing, chopping and dicing - the emphasis being on the number 3 (San).

STEEL:

Yukihiro San uses only Shirogami #1 for his kitchen knives, which is very reactive and delicate, but unparalleled in its sharpness.

Shirogami #1 is one of the purest steels, and consequently one of the easiest to sharpen. Its characteristics make Shirogami popular with traditional Japanese blacksmiths and sushi masters. The advantage of Shirogami #1 is that it has a very fine, delicate sharpness, is easy to grind and stays sharp for a very long time. It will require a little more attention in maintenance. The blade will acquire a protective patina with use.

KNIFE CARE:

The steel will gradually acquire a patina, which only endows this knife with more charm. Do not wash this knife in a dishwasher, but rather wash it by hand and wipe it with a dry cloth. The advantage of having a blade made of high carbon steel is the fine sharpness, ease of sharpening, and long edge retention. We recommend the occasional coat of knife maintenance oil to protect the blade from external influences.

→ Read more about patina on our blog.

LAMINATION:

The blade was laminated with soft iron, which is iron with only a small amount of carbon added to it. Laminating the blade improves its structural integrity, as the knife’s core is made of hard—and therefore brittle—high-carbon Aogami #2 steel that is prone to breakage on its own.

⚠️ Due to its purity and lack of any added elements such as chromium (Cr), soft iron doesn’t resist corrosion well. Therefore, the upper laminated part can also develop rust when not taken care of properly.

→ Yukihiro-san laminates the knives himself in his smithy because he sees this as a crucial step in the processing of the blade. The process of laminating different metals is very complex, and most smithies use pre-laminated materials.

GEOMETRY:

It has a double bevel (symmetrical) blade.

BLADE FINISH:

The blade sports a beautiful black Kuro-uchi finish.

The look of the knife reflects the blacksmith's philosophy and has a touch of rusticity and robustness that comes with the purely handmade blade. The knife has been created with a great deal of pride and skill.

HANDLE:

The Japanese Wa handle is oval and made in cherry wood with a plastic ferrule. It fits perfectly in the left and right hand.

BLACKSMITH:

Yukihiro Sakai is a young blacksmith from Kumamoto (Kumamoto Prefecture on the island of Kyushu). He trained with Nishida-san [Nishida Hamono]. Yukihiro-San's recent work is focused on Shirogami #1 with a kuro-uchi finish and evenly ground and flat profiles. His knives are affordable but of superior quality. We anticipate that over the years, the prices of his products will rise due to the superb craftsmanship and his growing popularity.

The Hinokuni Santoku is a versatile kitchen knife made entirely by hand by blacksmith Yukihiro-san at his smithy in Kumamoto in the south of Japan. The Hinokuni collection is hand-forged from Shirogami #1 steel laminated in soft iron, so sharpening will be nothing but pure pleasure. Few blacksmiths make their own knives completely in every step of the process from raw material to finished product, and Yukihiro-san is one of them. Working with raw materials is challenging and difficult, but the blacksmith insists on it because he believes that this step is crucial for the quality of the final product. The result of such a long and hard process are sturdy and heavy knives that are real workhorses. ❗️ Because they are forged by hand and in small quantities, they take a while to arrive, so here's some good advice: if one of the knives from the Hinokuni series is on your wish list, get it while it's still available. 🌋 Hinokuni means the land of fire, a nickname for Kumamoto Prefecture, home to the famous volcano Mt. Aso. BLADE SHAPE:The longer (210mm / 8.3) and wider (52mm / 2) santoku is a versatile kitchen knife that excels at all kinds of chopping and cutting on the kitchen cutting board. The wide blade allows easy transfer of ingredients from the board to the pot, and the extra weight can be used to cut through tougher ingredients (🚨 but not through bones!). Thanks to its long and thin cutting edge, this knife has no problem with longer cuts and finer techniques such as chopping garlic, dicing or julienne. The cutting edge is fairly straight (giving santoku a limited rocking motion), while the spine of the blade curves towards the tip continuously at an approximately 60-degree angle, making it resemble a sheep's foot. The Japanese word Santoku roughly translates to “knife of three virtues” and may refer to the wide variety of ingredients that the knife can handle: meat, fish and vegetables, or to the tasks it can perform: slicing, chopping and dicing - the emphasis being on the number 3 (San). STEEL:Yukihiro San uses only Shirogami #1 for his kitchen knives, which is very reactive and delicate, but unparalleled in its sharpness. Shirogami #1 is one of the purest steels, and consequently one of the easiest to sharpen. Its characteristics make Shirogami popular with traditional Japanese blacksmiths and sushi masters. The advantage of Shirogami #1 is that it has a very fine, delicate sharpness, is easy to grind and stays sharp for a very long time. It will require a little more attention in maintenance. The blade will acquire a protective patina with use. KNIFE CARE:The steel will gradually acquire a patina, which only endows this knife with more charm. Do not wash this knife in a dishwasher, but rather wash it by hand and wipe it with a dry cloth. The advantage of having a blade made of high carbon steel is the fine sharpness, ease of sharpening, and long edge retention. We recommend the occasional coat of knife maintenance oil to protect the blade from external influences. → Read more about patina on our blog. LAMINATION:The blade was laminated with soft iron, which is iron with only a small amount of carbon added to it. Laminating the blade improves its structural integrity, as the knife’s core is made of hard—and therefore brittle—high-carbon Aogami #2 steel that is prone to breakage on its own. ⚠️ Due to its purity and lack of any added elements such as chromium (Cr), soft iron doesn’t resist corrosion well. Therefore, the upper laminated part can also develop rust when not taken care of properly. → Yukihiro-san laminates the knives himself in his smithy because he sees this as a crucial step in the processing of the blade. The process of laminating different metals is very complex, and most smithies use pre-laminated materials. GEOMETRY:It has a double bevel (symmetrical) blade. BLADE FINISH:The blade sports a beautiful black Kuro-uchi finish. The look of the knife reflects the blacksmith's philosophy and has a touch of rusticity and robustness that comes with the purely handmade blade. The knife has been created with a great deal of pride and skill. HANDLE:The Japanese Wa handle is oval and made in cherry wood with a plastic ferrule. It fits perfectly in the left and right hand. BLACKSMITH:Yukihiro Sakai is a young blacksmith from Kumamoto (Kumamoto Prefecture on the island of Kyushu). He trained with Nishida-san [Nishida Hamono]. Yukihiro-San's recent work is focused on Shirogami #1 with a kuro-uchi finish and evenly ground and flat profiles. His knives are affordable but of superior quality. We anticipate that over the years, the prices of his products will rise due to the superb craftsmanship and his growing popularity.

Should I Buy a Gyuto or Santoku Knife? - Hasu-Seizo14 Jul 2023

Should I Buy a Gyuto or Santoku Knife? - Hasu-Seizo14 Jul 2023- 10 Most Popular Japanese Santoku Knives for 2024 - The Jerusalem Post14 Jul 2023

Coltello Santoku giapponese, 18 cm, 5000 MCD - Miyabi14 Jul 2023

Coltello Santoku giapponese, 18 cm, 5000 MCD - Miyabi14 Jul 2023 67-layer Damascus Santoku Knife Japanese Chef Knife Forged From Japanese VG10 Steel RUTHLESSLY Sharp Edge14 Jul 2023

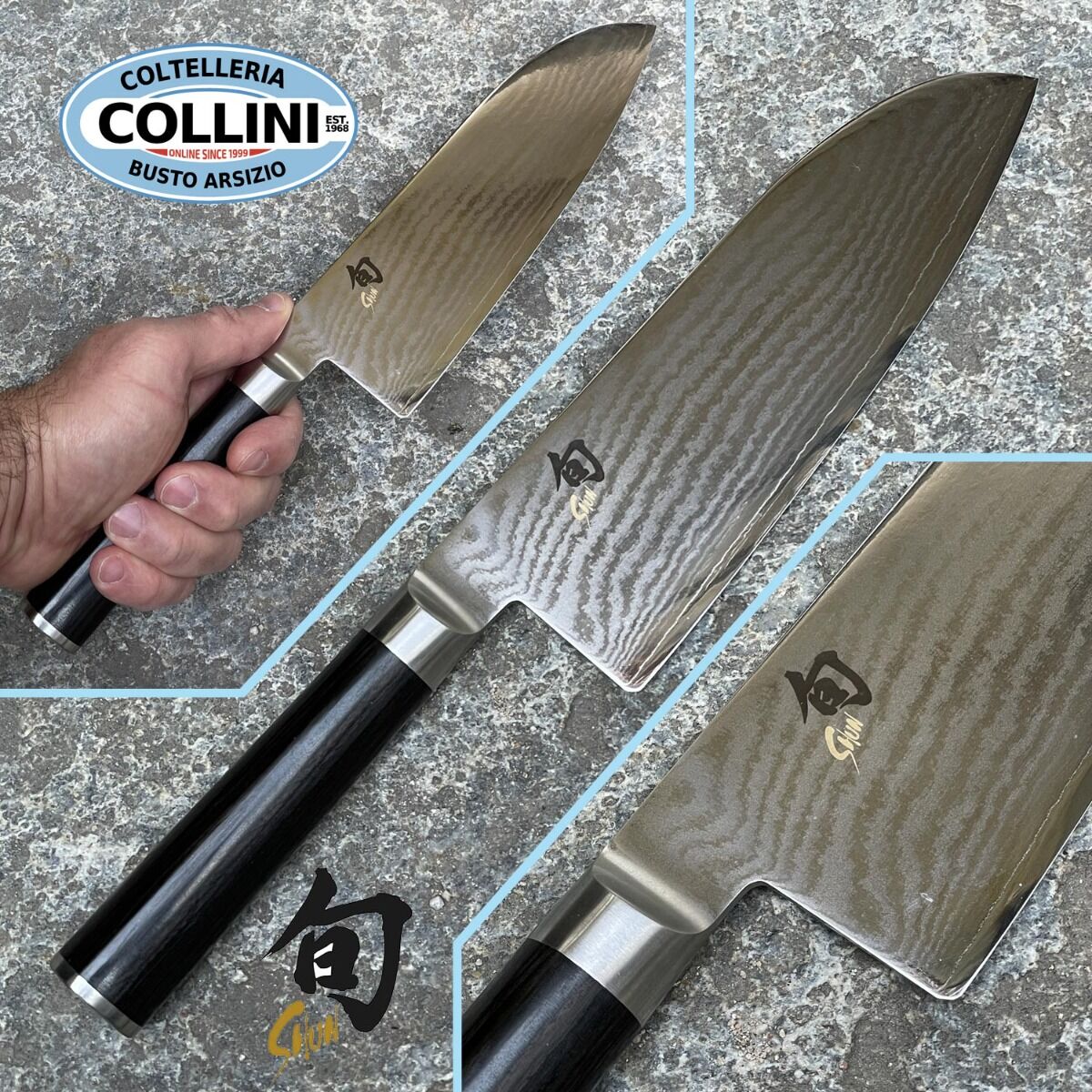

67-layer Damascus Santoku Knife Japanese Chef Knife Forged From Japanese VG10 Steel RUTHLESSLY Sharp Edge14 Jul 2023 Kai Japan - Shun DM-0717 - Wide Santoku Knife 190mm - coltelli cucina14 Jul 2023

Kai Japan - Shun DM-0717 - Wide Santoku Knife 190mm - coltelli cucina14 Jul 2023 Tsubazo, Japanese Santoku kitchen knife cm. 17.614 Jul 2023

Tsubazo, Japanese Santoku kitchen knife cm. 17.614 Jul 2023 Kanetsugu Classic Hammered Wa Series CHW-2 Wa Santoku 175mm (6.8 Inch)14 Jul 2023

Kanetsugu Classic Hammered Wa Series CHW-2 Wa Santoku 175mm (6.8 Inch)14 Jul 2023 YuiSenri GINSAN /Silver #3 Stainelss Japanese Style Santoku 165 mm14 Jul 2023

YuiSenri GINSAN /Silver #3 Stainelss Japanese Style Santoku 165 mm14 Jul 2023 JCK Original Fu-Rin-Ka-Zan White Steel No.2 Wa Santoku Knife14 Jul 2023

JCK Original Fu-Rin-Ka-Zan White Steel No.2 Wa Santoku Knife14 Jul 2023 Knife 67 Layers Damascus Steel Kitchen Knives Japanese Knife Santoku Steel - 7 Inch - Aliexpress14 Jul 2023

Knife 67 Layers Damascus Steel Kitchen Knives Japanese Knife Santoku Steel - 7 Inch - Aliexpress14 Jul 2023

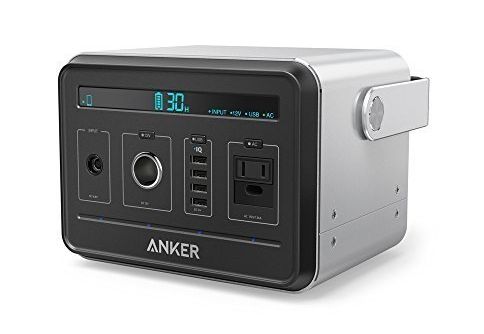

Con questo gigantesco power bank da 120600 mAh direte addio alla presa elettrica14 Jul 2023

Con questo gigantesco power bank da 120600 mAh direte addio alla presa elettrica14 Jul 2023 Lotbun Tagliasigari in Acciaio Inossidabile, Taglia Sigari per Sigari Toscani e Sigaro Cubano, Accessori per Sigari Cubani, per Tagliare la Parte Finale del Sigaro : : Casa e cucina14 Jul 2023

Lotbun Tagliasigari in Acciaio Inossidabile, Taglia Sigari per Sigari Toscani e Sigaro Cubano, Accessori per Sigari Cubani, per Tagliare la Parte Finale del Sigaro : : Casa e cucina14 Jul 2023 Te lo dico con una Matita (Paperback)14 Jul 2023

Te lo dico con una Matita (Paperback)14 Jul 2023 Assassin's Creed Valhalla PS5 Review14 Jul 2023

Assassin's Creed Valhalla PS5 Review14 Jul 2023:max_bytes(150000):strip_icc()/Southern-Living-Coconut-Chiffon_Cake_002-785fe7324ffc42ca94dedf9562e1f51b.jpg) Coconut Chiffon Cake Recipe14 Jul 2023

Coconut Chiffon Cake Recipe14 Jul 2023 PRIMA BRUCIO UNA TEGLIA, POI FACCIO LA FOCACCIA NELLA TEGLIA BRUCIATA, VIENI A VEDERE!14 Jul 2023

PRIMA BRUCIO UNA TEGLIA, POI FACCIO LA FOCACCIA NELLA TEGLIA BRUCIATA, VIENI A VEDERE!14 Jul 2023 Dispositivo di rimozione del tartaro dentale elettrico dispositivo di pulizia dentale detergente per denti irrigatore rimuovi tartaro Scaler sbiancamento dei denti cura dei denti - AliExpress14 Jul 2023

Dispositivo di rimozione del tartaro dentale elettrico dispositivo di pulizia dentale detergente per denti irrigatore rimuovi tartaro Scaler sbiancamento dei denti cura dei denti - AliExpress14 Jul 2023- Boule elettrica - Arredamento e Casalinghi In vendita a Roma14 Jul 2023

Immagini Stock - Vista Ad Alto Angolo Di Donna Attraente In Pigiama Con Cuscino In Mano Sul Letto. Image 11156734714 Jul 2023

Immagini Stock - Vista Ad Alto Angolo Di Donna Attraente In Pigiama Con Cuscino In Mano Sul Letto. Image 11156734714 Jul 2023 SquishKits – Appiccicoso, colorato e divertente! Giochi antistress per gattini. – Corano Gioielli, accessori moda14 Jul 2023

SquishKits – Appiccicoso, colorato e divertente! Giochi antistress per gattini. – Corano Gioielli, accessori moda14 Jul 2023